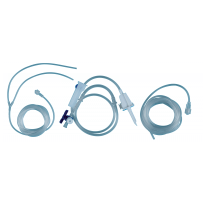

Sterile irrigation set

- Best quality / price ratio Best quality / price rat…

- Sterile Sterile

- Karton mit 10 Stück Karton mit 10 Stück

Nous contacter : 01 48 01 32 89

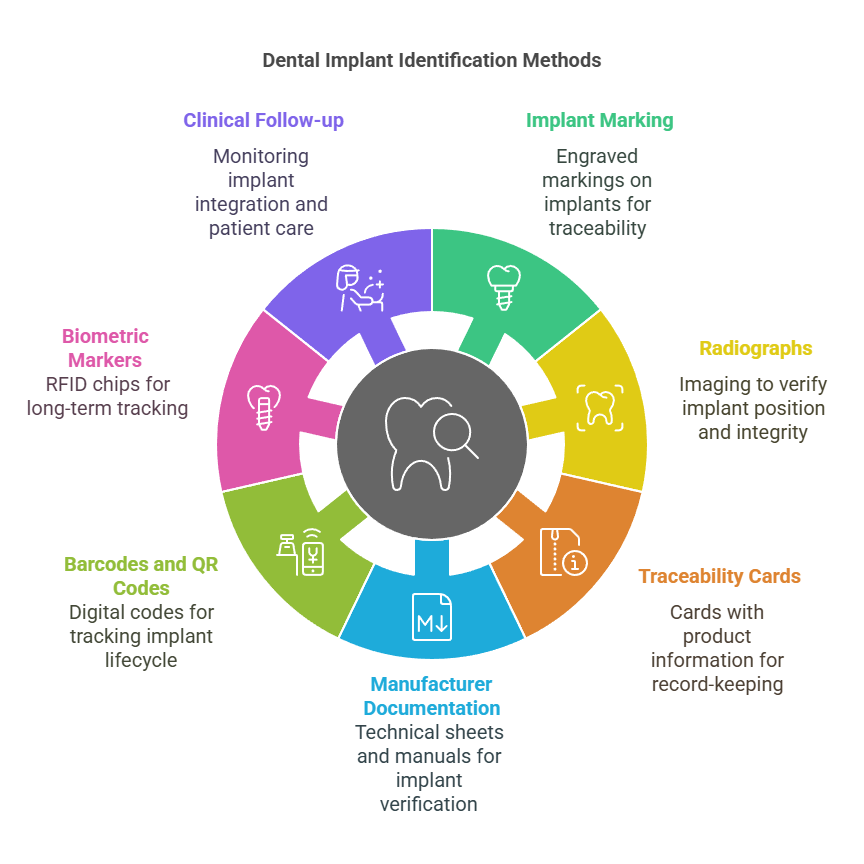

HYGITECH Academy invites you to watch this clinical case on dental implant placement after bone...

Further to the anatomical-histological review of periodontal and peri-implant tissues, this...

Implant unit motors are necessary equipment for placing dental implants. They are composed of a...

The dental implant motor is a key piece of equipment for successful surgical procedures in oral implantology. Its precision, reliability, and features directly impact surgical safety, the quality of osteotomy, and the comfort of both the practitioner and the patient. Given the wide range of models available on the market, it is essential to understand the most relevant selection criteria to make an informed choice suited to your clinical practice.

The motor's power (expressed in watts) and torque (expressed in N·cm) are critical parameters. A high-performance motor should allow for precise drilling even in dense bone, without overheating or slowing down.

Recommended torque: at least 40 N·cm, though some high-end motors go up to 70 N·cm, which is useful for placing implants in dense bone (types D1 or D2).

Electronic regulation of torque and speed: ensures consistent torque even at low speeds, which is crucial during implant insertion.

A good implant motor should offer a wide range of speeds (typically from 300 to 40,000 rpm) to suit the different stages of the procedure:

Initial bone drilling: speeds between 800 and 1200 rpm, usually with irrigation.

Threading or implant insertion: slow speeds around 15 to 50 rpm to ensure controlled screwing.

Effective sterile external irrigation is essential to minimize the risk of thermal necrosis (>47°C). The motor should be equipped with:

An integrated peristaltic pump, quiet and easy to clean.

Adjustable flow rate (typically between 30 and 100 mL/min) to tailor cooling based on the surgical phase.

Sterile tubing compatible with the system.

The contra-angle must be perfectly matched to the motor to ensure reliable torque transmission. A 20:1 reduction contra-angle is recommended, as it meets implantology requirements. Additional criteria to consider:

Automatic or manual lubrication.

Autoclavable at 134°C.

Short head and ergonomic shape for improved visibility.

The interface quality contributes to the overall ergonomics of the surgical procedure. Look for:

A touchscreen or LED display, readable even with gloves.

Pre-programmed settings tailored to surgical sequences.

The ability to save custom protocols, especially according to the implant systems used.

A good implant motor must comply with strict aseptic standards:

Smooth, easy-to-clean surface.

Autoclavable accessories.

Compatibility with sterilization protocols.

Some models include a USB memory or Bluetooth connection to record procedure parameters (traceability, quality audits).

Choosing a reliable manufacturer or distributor is crucial. The availability of spare parts, responsiveness of after-sales service, and user support are often underestimated but essential in a demanding professional environment.

Dental surgical instrument display

Dental surgical instrument display